Matti Monojet 330

High performance inkjet roll-to-sheet press

This high-performance press can produce 600+ duplex printed pages per minute. The press takes full advantage of Matti Technology AG’s advanced inkjet writing system. The press includes an unwinder, single-engine-duplex (SED) mono print engine, a rotary cutter and a continuous offset stacker for variable document sizes. An optional in-line primer unit can be installed to apply primer fluid.

The Monojet 330 can run resolutions of 600x600dpi, 600x1200dpi or 1200x1200dpi.

Inks are available with excellent performance on coated and uncoated media.

The system can run MICR inks, ideally suited for checks printing.

All-in-one solution

The modern and streamlined design of the press features an unwider, primer, CMYK duplex printer along with offset continuous cutter and stacker modules, all managed from a centralised touch screen interface.

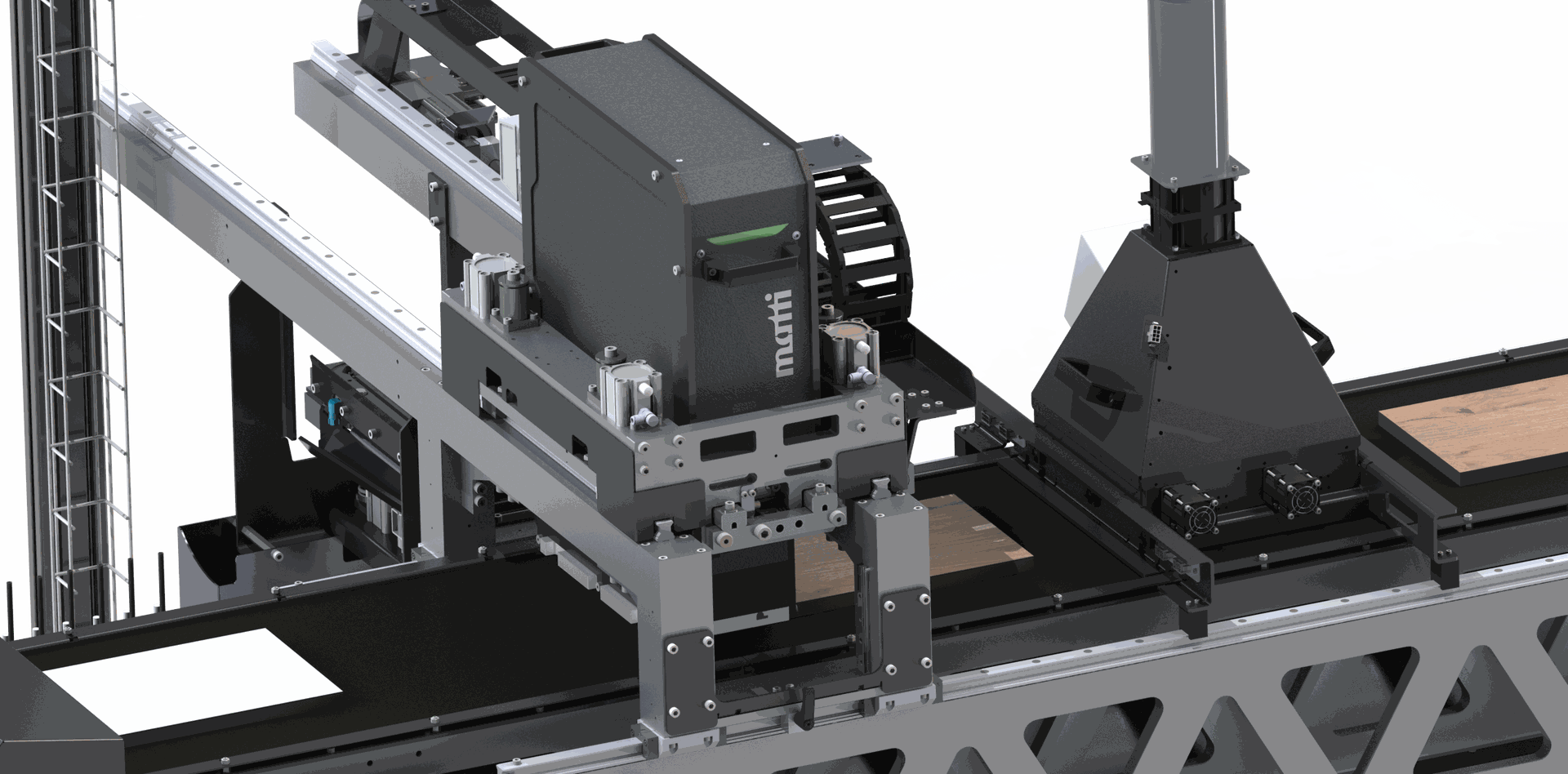

Single-Engine-Duplex

Single-Engine-Duplex (SED) printing facilitates the creation of duplex pages with a space-saving printer that runs the web concurrently, reducing both the factory footprint and maintenance time.

The Matti MonoJet 330 is powered by the Matti Technology AG high-performance inkjet writing system. The press is designed as an all-in-one solution to produce mono or CMYK printed book blocks and comes in a compact footprint.

- Maximum web width: 320mm (310mm with paper shift)

- Maximum print width: 310mm

- Maximum web speed: 150m/min (Roll to sheet); 200m/min (Roll to Roll, at 600 x 600 dpi)

- Paper weight: 80-160gsm (lower paper weights may be possible and need to be tested in advance)

- Approximate footprint: 6.5x2.28x2.05meters (LxWxH)

- Resolution: up to 1200x1200dpi

- Inks: Water-based pigment inks, MICR inks

- Integrated Unwind-System with:

- Lifting arm to lift paper roll of diameter of up to 54 inches

- Web cleaner

- Dancer roller for paper tension adjustment

- Web guide for 1st path

- Connection pins to attach to the next system (Print Tower)

- Print-Tower:

- Matti Technology AG inkjet writing system for mono and CMYK printing, including controller and ink supply system

- Infeed roller with pneumatic nips (2x)

- Tach roller for paper speed (2x)

- Rollers to support paper underneath print head

- Infrared dryer (48 kW)

- Air-turn-bar

- Outfeed roller with pneumatic nips

- Cutter and Stacker Unit:

- Rotary cutter unit 6 inches - 16 inches cut length

- Stacker unit with 2 streams (sample gate / normal stream)

- Stacker unit for cut off lengths about 6 inches - 16 inches

- Job separation by printed mark

- Digital Front End (DFE):

- Matti Technology AG Digital Frontend

- Controls the entire press - operation from one single point

- PDF, AFP and IJPDS workflow

- High-accuracy ink estimator for cost-per-page analysis